gamma irradiation

A “cold” sterilization technique

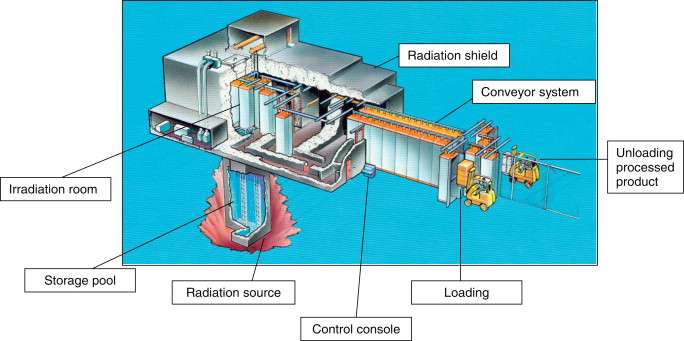

Gamma Irradiation is a physical means of sterilization or decontamination. Gamma Irradiation kills bacteria by breaking down bacterial DNA and inhibiting bacterial division. Essentially, energy passes through the treated product disrupting the organic processes that cause contamination. Gamma Irradiation exposes products or substances to gamma rays. Gamma rays are electromagnetic radiation of very short wave lengths (similar to UV). Gamma rays are used for many other purposes from communications (radio waves) to cancer treatment applications. The most common source of gamma rays for irradiation processing comes from the radioactive isotope Cobalt 60. It is manufactured specifically for the Gamma Irradiation process. Gamma Irradiation is known as a ‘Cold Process’ as the temperature of the processed product doesn’t significantly increase. It is not dependent on humidity, temperature, vacuum or pressure. Thus, the packaging remains intact, as the seals are not stressed. The only variables are source strength and exposure time. Products or substances are exposed to gamma rays in a special chamber called the irradiation room. This chamber is constructed of two meters of reinforced concrete surrounding the irradiation room, which ensures that ionizing radiation does not escape to the outside room. Cobalt 60 pellets are sealed inside stainless cylinders known as source pencils. These pencils are arranged in a moveable rack and stored in a pool of pure water. The source rack normally is normally in one of two positions: the storage position (submerged in a pool of water) or the raised operating system. Products to be processed are loaded onto automatic conveyor system and transported into the irradiation room. The products are then circulated to ensure an even exposure to ionizing energy. The received dose is determined by product density, and exposure time.

International Atomic Energy Agency

OUR irradiation PROCESS

Automatic Pallet Irradiator